When I first started learning about cars and engines there were so many words thrown around. I had no idea what people were talking about. It was like a different language to me. I always wondered how an engine works and what made it be able to make so much power.

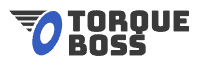

Things started to make sense when I got familiar with all the parts of the engine and was able to see them together. What helped me the most was completely taking apart a small block Chevy 350 and putting it back together. I know not everyone has access to a small block or has all the right tools so I’ll do my best to explain how engines work.

History

History of the internal combustion engine goes back all the way to Leonardo Da Vinci. He imagined and put words on paper describing how an engine would work. People built on each other’s ideas until the late 1800’s when Nikolaus Otto came on the scene.

Nikolaus was a German engineer. He built some of the first working combustion engines in the world based on his ideas and ideas from others. He built atmospheric engines and later four stroke engines. I was lucky enough to see a working replica of his compression-less engine in person. It is very quiet and uses hydrogen as the fuel source.

The next person to mention is Henry Ford. He popularized the motor vehicle and created the automated assembly line. He and his engineers introduced their Ford V8 flathead. That kicked the automobile craze in to high gear. Modern cars today aren’t flatheads but many still use the V8 configuration.

Types of Engines

Internal combustion technology has come a long way since the 1800’s. It’s amazing the basic functionality hasn’t changed much. We’re still harnessing the power of controlled explosions to move a vehicle. The basics haven’t changed in hundreds of years!

Auto makers today have made advancements in fuel efficiency and power production. They’ve also advanced the manufacturing process. Auto makers can now bring vehicles to market quicker and faster. Reliability and longevity is much better compared to the past.

Let’s look at the types of engines most common today.

V Configuration

The V is the most common engine configuration in use today. Henry Ford made this engine popular in the 1930’s.

It’s called a V because the cylinders are in the shape of a V. Four on one side and four on the other. The eight refers to there being a total 8 cylinders.

This configuration is very flexible for manufacturers. It’s very easy to add more cylinders during the design phases of an engine. You’ll even find Jaguars and other manufacturers with V12’s.

The main benefit of the V configuration is the power it can create. But it comes at a price because of the weight. Remember power to weight ratios can affect your performance.

Keep in mind the more cylinders you have the more maintenance there can be as well.

Inline

I’ve heard these engines called in-line 6 or straight 6 because the cylinders are all in line with each other. Pull the head off of this engine and you’ll see the combustion chambers all in one line, not in a V.

The good part about inline engines is they are smaller than V engines and weigh much less. This makes them great for compact cars and is very popular in Europe. A smaller engines means better fuel economy but less power.

Flat or Boxer

The boxer engine gets its name because it mimics the movement a boxer does when punching. The cylinders lay flat or horizontal to each other.

Porsche and Subaru are popular cars that use the boxer style engine. Next time you see a Subaru, take a listen and notice the distinct sound the exhaust makes. It’s very different sound from a V8.

The good part of the boxer engine is the low center of gravity of the engine. Think about it. If the cylinders are laying flat, you don’t have the vertical height of what a V8 would take up. You get better handling ability which can be a big deal in racing when cornering.

The negative part of this is the engine is wider and the engine bay needs to be designed around that. Nothing that some smart engineers can’t fix!

Rotary

Rotary is almost a completely different concept. No pistons, but rotors. Rotors! How does it even work? I had to look at a diagram of the engine to understand it.

The rotor looks like a triangle with teeth. The contained explosions move the rotor around a housing. This unique concept has some great advantages like fewer moving parts.

One of the side effects is the additional heat it creates. Engineers account for the extra heat during the design process. Rotary engines can sometimes create higher emissions that an inline or V.

The rotor engine can rev higher than other engine types. Check out this Mazda which is rev limited to 11,500 RPM:

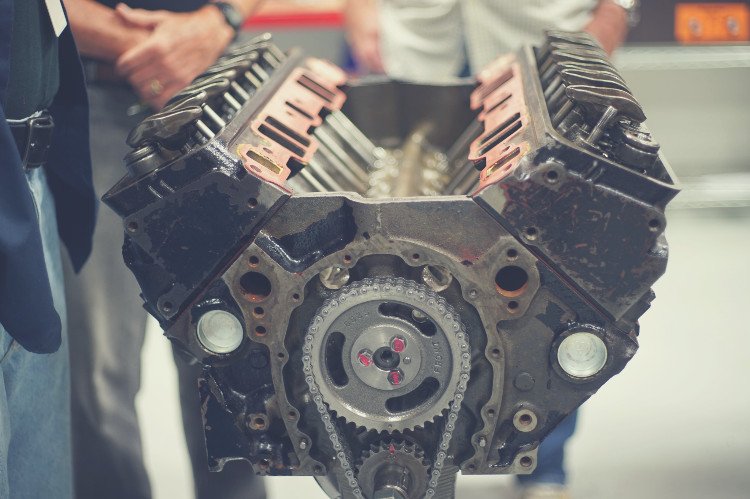

Infographic: How A Four Stroke Engine Works

How Four Stroke Engines Work

I grew up hearing my dad always say how much he disliked two stroke engines. I remember him trying to start a two stroke weed eater after winter and the thing would never start!

A four stroke engine always runs so much smoother and starts up easier. My focus here is four stroke. I won’t go in to other types like diesel, but the principle of internal combustion is the same. It’s the implementations that are different.

If you want to remember the stroke sequence, remember this: suck, squeeze, bang, blow. It’ll all make sense here in a minute! Wikipedia has a great graphic showing the process.

Intake

First, the piston is all the way to the top. This is called top dead center (TDC). When the piston goes down to bottom dead center (BDC), the intake valve is opened. Air and fuel mixture rushes in from the carb to the combustion chamber.

Compression

At bottom dead center, the intake valve closes, the piston starts to go back up and compresses the air. The crankshaft has made one full revolution at the end of the power stroke.

Power

Then the fire is lit! This is where the power is generated. The explosion during the power stroke drives the piston down to bottom dead center. None of the valves are open during the power stroke.

Exhaust

After the piston is bottom dead center from the power stroke it goes back up. The exhaust valve opens to get rid of the fumes out the headers. The crank shaft has now made two full revolutions.

That’s the cycle of a four stroke engine! Remember: suck, squeeze, bang, blow. That’s all you need to know and is a quick and easy way to remember everything.

Engine Components

There are a lot of moving parts in an engine and if you haven’t heard some of the names of the parts before it can be confusing. Let’s run through the names of everything and it will start to come together.

Engine block

The block or cylinder block is usually cast out of iron or an aluminum alloy. This is the main body of the engine and houses the cylinders. The explosions will expel most of the heat to the block. There are many cooling passages for water, oil, and routing for other parts of the engine.

Cylinder head

The heads cover and seal the top of the cylinder chamber. There are two heads in a V configuration, one for each set of four cylinders. Change out heads for higher compression. Some people even swap them out for aluminum heads.

Pistons

Pistons move down the compression cylinder after the explosions occur. They create the motion that drives the crankshaft around. Pistons are a cylinder shape and are connected to rods which turn the crankshaft.

Piston Rings

Piston rings are a very precise, thin, metal ring that fits in slots around the piston towards the top. They help create a seal for combustion and keep the cylinder chamber lubricated with oil.

Crankshaft

Pistons connect to the crankshaft by rods. The rods push the crankshaft around creating rotational force. An unbalanced crankshaft can cause major problems. Adjust the counterweights to keep everything in balance.

Valves

There are two types of valves: intake and exhaust. One allows air in and the other lets it out. Pretty simple right? Most auto makers design one of each per cylinder. Other manufacturers can have multiple valves per cylinder.

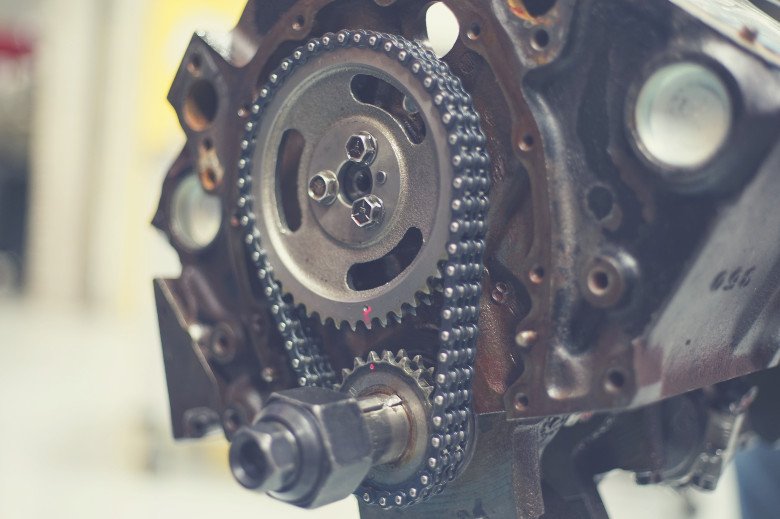

Timing Belt

This is what keeps the camshaft in sync with the crankshaft. The valves can now open and close at the right time and in sync. Timing belts are made out of rubber with teeth inside for grip. A timing chain does the same thing but is metal and looks like a bicycle chain. If timing is off, this is where you make adjustments.

Camshaft

The valves need to open at the right time in the cycle. So the camshaft controls their timing. If you look at a camshaft, you’ll see these lobes that raise and lower as you turn it. This is what controls the opening and closing of the valves in the correct sequence.

Spark plugs

The engine needs a spark to ignite the explosion. The spark plug is an electrode that provides a controlled spark to ignite the fire. Look at the bottom of a spark plug and you’ll see a center and side electrode. The side electrode needs a specific gap according to the manufacturer. This creates the correct arc which ignites the explosion.

Fuel Injectors

Modern cars use fuel injectors to add an atomized mixture of fuel and air for the explosion. Carburetors in classic and antique cars suck in air and add fuel to create the mixture. The advantage of fuel injectors is they need little maintenance compared to carbs. Carbs can be notorious for needing to be cleaned if they get dirty or clogged.

Summary

That’s the basics of how an engine works! There are more systems to a vehicle but now that you have a general understanding of the cycles of an engine. You also know the names of the main components.

Engines are fine tuned machines with very tight tolerances. They will function with many years of use. Auto makers will continue to refine the engine in the future. It’s common to see 100,000 mile warranties today as a standard offering! What if Henry Ford offered that same warranty in the 1930’s? We’ve come a long way since then.

I’m definitely intrigued to see where things continue to go in the future. Especially with electrical vehicles now coming of age!